Developed originally for Bradley Wiggins’ Hour Record in 2015, the nanotube chain (NTC) process is the culmination of thousands of hours of research and development into drivetrain optimisation by Dr Martin Mathias AKA ‘Doctor M’ and Muc-Off MD Alex Trimnell AKA ‘Mad Developer’.

For special occasions like the Tour De France, the guys at Team INEOS send their chains over to us for the full NTC treatment. Here’s a run-down of the process step-by-step.

STEP 1

Doctor M runs one of the chains through the Muc-Off dynamometer using a simulated load specific to a road-race to measure its performance pre-treatment.

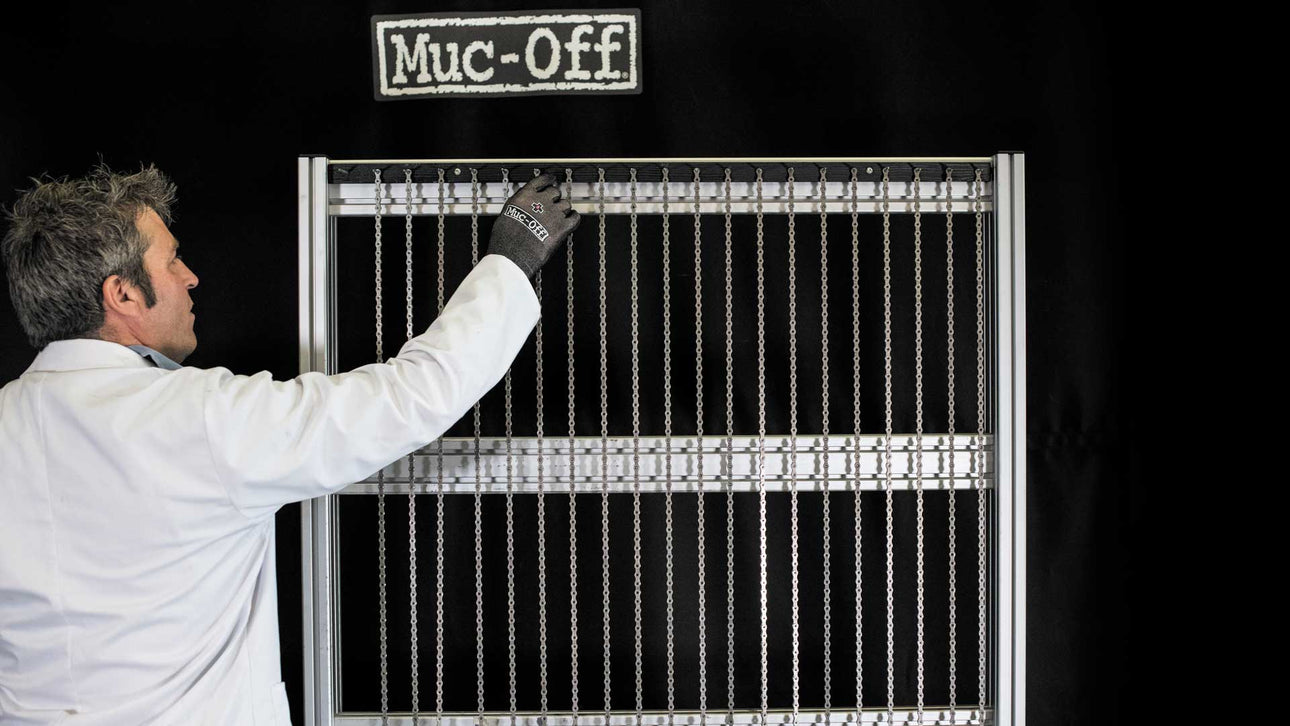

STEP 2

A sonic cleanse for the chains all together. They are placed in a custom-built tray and dipped in a heated ultrasonic bath which uses our Drivetrain Cleaner and ultrasound waves to remove foreign particles and contaminates. Because of the way chains are manufactured, there is an oil-based stock chain lubricant which needs to be removed fully before the nanotube treatment.

STEP 3

Rinsed with cold and de-ionised water. The water needs to be clear of any metals and minerals to avoid any chances of rusting.

STEP 4

The chains are then dried in our oven for 40 minutes to ensure all moisture is evaporated completely.

STEP 5

Round two of the ultrasonic cleaning, this time done individually and in smaller baths using a Muc-Off proprietary non-chlorinated cleaner. This ensures the chain is completely free of contaminates. The smaller baths provide an easier way to control the chemical fluid (2 litres vs 25 litres!), which means more effective cleaning.

STEP 6

The chains are once again dried for 20 minutes in the oven.

STEP 7

The chain is then hand-treated with a proprietary nanotube formulation in another heated ultrasonic bath. The nanotube ingredients are composed of graphene and rolled into a microscopic tube. Although a chain’s surface may look smooth to the naked eye, it’s in fact quite rough and ragged. As a chain is run through it, these jagged edges catch on each other which causes friction. The nanotube fills these gaps, creating a slippery smooth surface that minimises metal-on-metal resistance.

STEP 8

Doctor M runs one of the chains through the dynamometer under the same load as pre-treatment to record the exact performance gains which are passed on to the team and recorded internally.

STEP 9

Once the team receives the chains, these need to be ‘bedded in’ for 4-6 hours to reach optimum lubrication state before being raced on. This process basically ensures all the nano-tubes have been pushed into the imperfections on the chain’s surface.

Muc-Off UK

Muc-Off UK

Muc-Off EU

Muc-Off EU

Muc-Off US

Muc-Off US

Deutsch

Deutsch

Espanol

Espanol

Francais

Francais

Italiano

Italiano

Nederlands

Nederlands

Polski

Polski